Have you checked your boards lately?

In June 1999 I took possession of MC 1939. It has been a great boat but,

late in the 2000 season, I was starting to experience some problems with the boards.

So, after competing in the 2001 Midwinters, I brought the boat home and pulled the boards.

In June 1999 I took possession of MC 1939. It has been a great boat but,

late in the 2000 season, I was starting to experience some problems with the boards.

So, after competing in the 2001 Midwinters, I brought the boat home and pulled the boards.

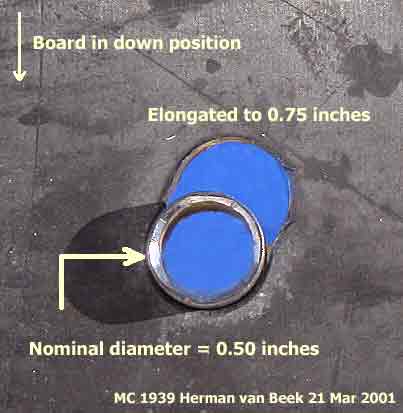

I was surprised at what I found after two seasons of sailing:

The nominal 1/2" board pivot hole had elongated to 3/4 inch!

I discussed the problem with Melges and ordered oil-impregnated bronze

bushings with an outside diameter of 3/4 inch (McMaster Carr part numbers shown below).

While stainless steel bearings have been installed by some, I preferred a bronze bushing

solution after comparing Brinell hardness numbers:

| Material |

Brinell Hardness Number |

| Stainless steel |

240 - 290 |

| Aluminum (6061-T6 alloy) |

95 |

| Bronze |

60 - 95 |

In other words, stainless will easily wear out aluminum, but aluminum will hardly

affect or be affected by bronze.

In other words, stainless will easily wear out aluminum, but aluminum will hardly

affect or be affected by bronze.

As you can see, the new arrangement consists of two concentric bronze bushings.

I used the outer bushing as a template and marked the board around the original

pivot hole. With a round file I easily expanded the hole to snugly fit

(hand tight) the outer bushing.

Before returning the board and bushings back to the boat, I ground down the outer bushing

by approximately 3/32". This is critical to the success of this arrangement. While

the inner bushing will be in firm contact with the board box wall, the outer bushing

MUST be allowed to move laterally along the inner bushing when the board moves laterally -

e.g. during a tack. The 3/32" difference in bushing length allows this lateral movement

to take place without undue stresses between the board andthe outer bushing.

Before returning the board and bushings back to the boat, I ground down the outer bushing

by approximately 3/32". This is critical to the success of this arrangement. While

the inner bushing will be in firm contact with the board box wall, the outer bushing

MUST be allowed to move laterally along the inner bushing when the board moves laterally -

e.g. during a tack. The 3/32" difference in bushing length allows this lateral movement

to take place without undue stresses between the board andthe outer bushing.

Two years later...

Two years later...

In January 2003, I decided to get my boards anodized and so I got to take a look at how

the bronze bushings had fared after two very active years of sailing - more than 20 regattas

and we sail pretty much year round in Texas!

I was pleasantly surprised at the small amount of wear showing.

The dimensions of the bearings were:

- 14.45 mm = inside diameter of outer bushing, and

- 14.43 mm = outside diameter of inner bushing.

Not bad!

Starting with model year 2003, Melges is pressing a single bronze bushing into the board instead of a

stainless steel one.

Here are part numbers from the McMaster Carr Web site (Catalog page 1002)

in case you need to work on your boards:

These are 1/2" long sleeve bushings, made out of SAE 841 porous sintered bronze

that are vacuum-impregnated with 18-20% SAE-30 oil:

- 6391K173 - 3/8" I.D. X 1/2" O.D. -- can also be ordered from Melges, and

- 6391K221 - 1/2" I.D. X 3/4" O.D. -- outside bushing if hole has wallowed out too much; Melges does

not stock this bushing.

Note: The slight oval shape of the board hole is still from the original deformation caused by

the stainless steel bushing that was in the board during the 1999 and 2000 sailing seasons.

Johnson Boat Works (JBW)

JBW used a solid 1/2 inch bronze shaft to support the board. These pictures show the board

pivot hole and shaft on MC1540 built by JBW in 1993.

Have you checked your boards lately?

Good luck and...See you on the starting line!

Herman van Beek

(Last updated on: 2/22/2004)